Pre‑Assembled Junction Boxes

Factory-built for reliable power distribution in industrial environments, with seamless site integration.

- Built-to-spec, tested, and documented

- UL/CSA compliant hardware and labeling

- Accelerates site energization and deployment

Control & I/O Systems

Engineered for automation, redundancy, and sustainability in high-density data center setups.

- Redundant architectures available

- Optimized for panel space and thermal performance

- Documentation ready for project handover

HDC Plug‑and‑Play Connections

Rapid, secure connects for HVAC, lighting, and power monitoring to minimize downtime.

- Rugged, coded interfaces

- Faster install & replacement

- Error‑proofed field terminations

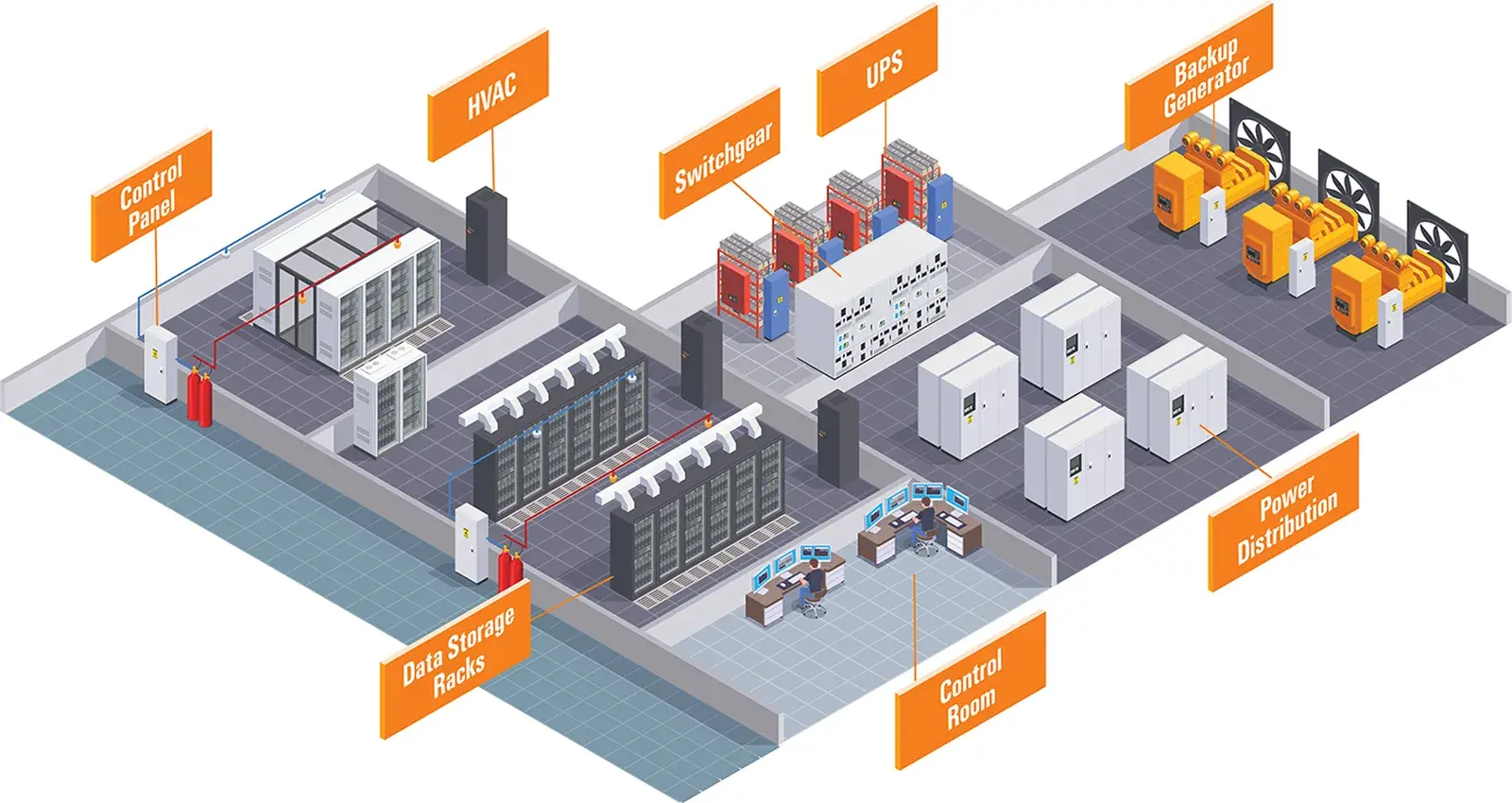

Build Faster, With Fewer Field Errors

Shift wiring and assembly off‑site. Speed commissioning across electrical rooms, white space, and support systems.

Why developers, EPCs, electrical contractors, OEMs, and panel builders choose Weidmuller

- Get assemblies engineered and factory-tested in Richmond, VA, delivered ready to install.

- Move wiring off-site to improve schedule reliability and reduce on-site variability.

- Standardize builds with labeled assemblies and complete documentation.

- Speed delivery with quotes in minutes and 10-day shipment on select rail builds.

- Scale programs across sites with consistent BOMs and change control.

- Rely on 175+ years of connection and automation expertise.

Built for U.S. Data Center Timelines

- Coverage in growth hubs: Northern Virginia, Dallas–Fort Worth, Phoenix, and more.

- Application coverage: power distribution and junction boxes; control and I/O rails; white space.

- System interfaces: HVAC, lighting, and power monitoring for fast on-site install.

- Documentation: submittal-ready packages and labeling aligned to U.S. standards.

Data Center Coverage — At a Glance

- PLCs, PAC controllers (with redundancy)

- Remote I/O, analog signal conditioning

- HMIs / Energy monitoring / Power analyzer

- Industrial Ethernet, security routers, remote access gateways

- Power supplies, UPS

- Terminal blocks, DIN rail, relays

- Circuit breakers, surge protection devices

- Enclosures & cable glands, cabinet lighting

- FrontCom service interfaces

- Power supplies, UPS

- Data connectors, RJ45 patch cords, SAI cordsets

- HDC heavy-duty connectors (high-power, outdoor housings, ModuPlug)

- PCB signal & power terminal blocks/connectors

- Single Pair Ethernet, M23 connection, motor connection

Frequently Asked Questions

What’s included in a typical modular assembly shipment?

Our pre-engineered modular assemblies enable seamless integration in data center panels for efficient scaling. They include pre-assembled, tested assemblies—delivered ready to install—such as terminal-rail builds and populated enclosures/junction boxes, with marking/labeling and documentation. Options can include remote I/O, controllers, HMIs, and HDC interfaces, plus pre-assembled cable/harness options for common PLC/DCS interfaces and HDC systems—ensuring flexibility for hyperscale or edge computing needs.

How do you handle compliance and certification?

Compliance is key to our U.S. data center solutions. We select components with North American approvals (e.g., UL/CSA, cULus) and include certificates and datasheets. UL file numbers and standards are available on request, ensuring safe, reliable high-density installations.

Lead times and scalability?

We prioritize agility in the fast-paced U.S. data center market, enabling phased rollouts for AI-driven expansions. Assemblies are produced in a controlled environment (e.g., our Richmond, VA facility), scaling to your needs. For qualifying builds, our Fast Delivery Service guarantees shipment in ≤10 days using defined top components; others are quoted to schedule. Your Weidmuller team scopes timelines, logistics, and phase gating to align with your demands.

Talk to an Engineer

Tell us about your timeline and scope. We’ll respond with a design consult, options, and a path to faster commissioning.